Turbine Upgrades

Gael Energy have gained expertise in addressing commonly encountered failures and offer a range of upgrade solutions to optimise turbine performance and minimise ongoing repair expenses for our clients.

We are able to implement a variety of different improvements either on site or within our state of the art workshop in Evanton and Mintlaw. In addition, we are continually looking to improve turbine performance and reliability through R&D processes, both through our own design and through collaboration with the original equipment manufacturers and third party design engineers.

C&F Upgrades

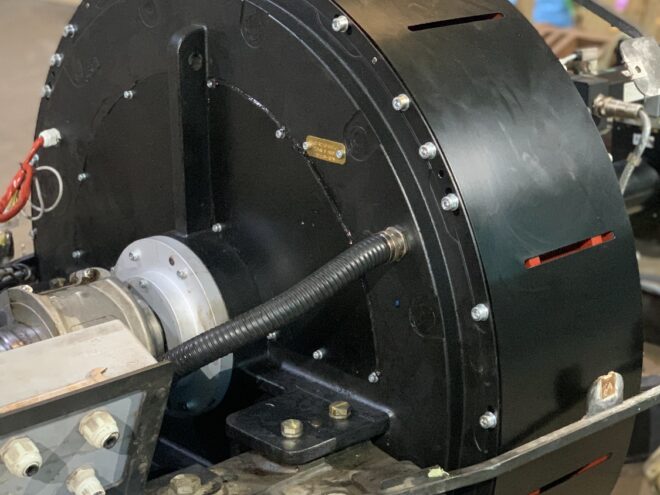

Radial Alternator

A new Radial generator can run at 80rpm and at full power is running at 75% of its available capacity; this means that it will never be under extreme duress which will increase the lifespan of the unit

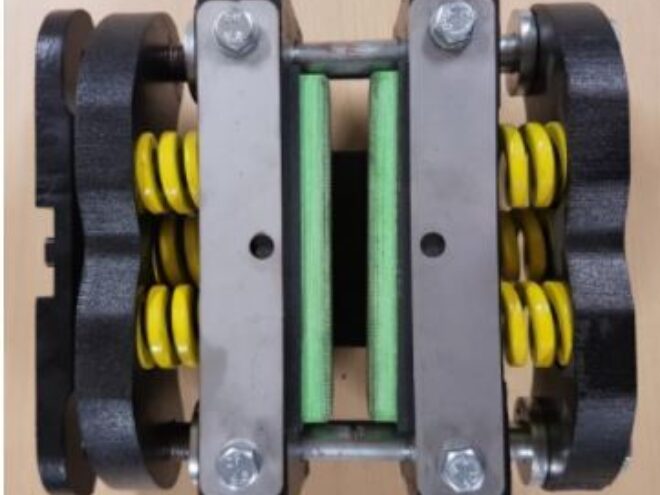

Blade Bearing

The Belville washer spring assembly - Belville washer spring applies a continuous loading on the taper lock bearing and as a result increases the operating life of the stub shaft bearing assembly.

The stub shafts are metal treated and nightrided and improved blade Shaft Bearings are fitted as part of the bevel washer assembly. New seals are fitted in the grease chamber to prevent grease leakage.

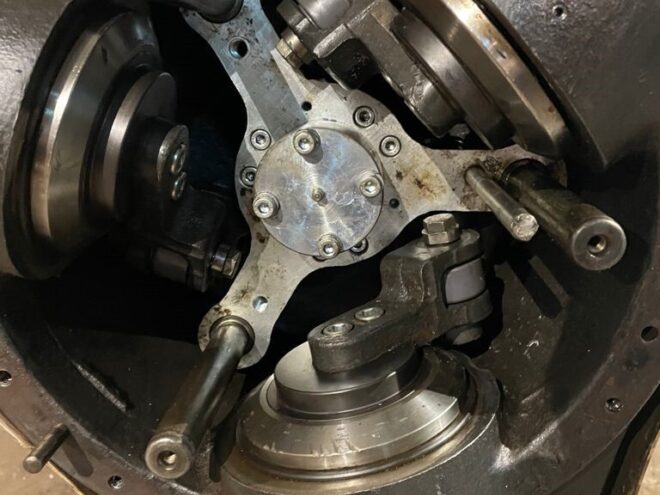

Pitch Damper System

We now fit a three pin guide system on the blade pitch assembly. This ensures an even balance and movement as the blade pitches. This will prolong the life of the pitch bearings and provide more accurate control of machine.

Slew brake calliper

We now fit improved slew brake calipers with increased clamping force to prevent the machine from rocking in high winds, increasing the life of the slew gearbox and motor. Furthermore, this goes some way to alleviating cable twist issues.

EL Power Inverter

EL Power Inverters are a perfect example of how technology has progressed since the original design of the C&F turbine. They have transformed the turbine’s ability to regulate speed in gusty conditions and as a result remove countless stresses from your wind turbine. They are considerably more reliable than the original inverter setups and can be remotely accessed so EL Power’s Engineers in Italy can assist with diagnostics and set up where necessary.

Brushless Motors

We now fit brushless slew and pitch motors for increased reliability. These motors have no wearing parts and are able to deliver increased torque and faster reaction times. Furthermore they offer increased protection to the PCB control boards as the do not draw power directly through the board.

Blade refurbishment and rebalancing

We have found that over time the blades absorb moisture from the atmosphere which will in turn disrupt the balance of the blades. If you are experiencing significant tower sway we can provide you with an exchange set of refurbished blades.